In the decades since the first Earth Day, the 22nd of April has become a global call to action, focusing attention on big environmental challenges and the shifts needed to ensure a healthy, livable planet for generations to come.

Clean energy solutions vary widely in their environmental footprint

The good news is that we now know how to create that healthy, livable planet, and we have technologies to get there. An electrified society powered by clean wind and solar power has the potential to stabilize the climate and begin to repair damage from over a century of fossil fuel dependence.

That is not to say that building that electrified future will be easy or that every decision will be obvious. The current grid evolved over a century and we now have to replace it with one powered by clean, but intermittent, renewable resources in just a few decades. Building adequate wind and solar power will be challenging enough, but we know that we will also need significant energy storage capacity, the linchpin of the clean energy system.

Fortunately, global energy storage deployments are beginning to accelerate. Over the next several decades, global demand for battery materials is expected to increase as much as 4,000 percent. As we transition away from fossil fuels, it will be essential that these materials come from responsible sources to ensure that the new clean energy economy is built on a sustainable foundation.

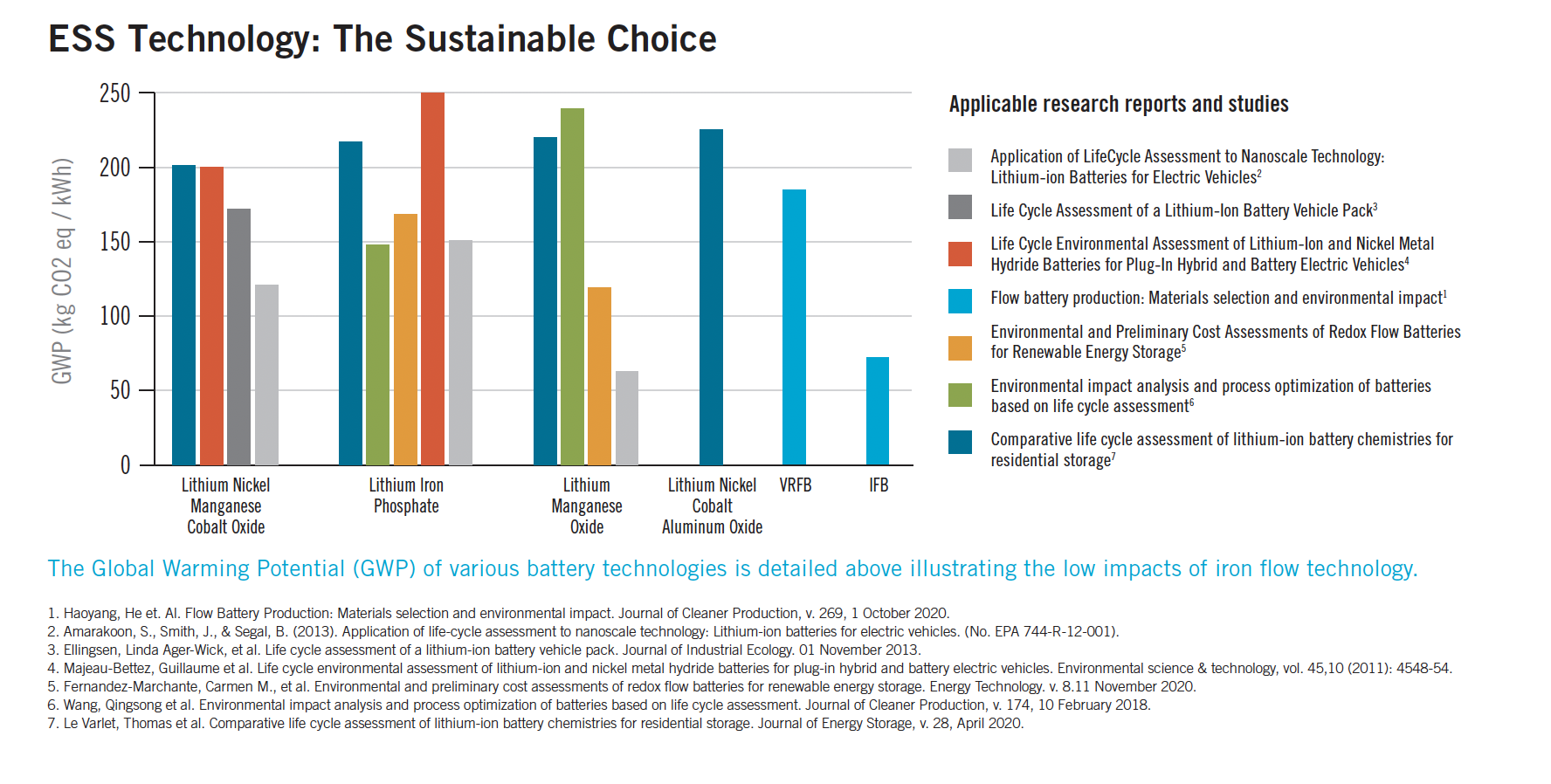

More energy storage will enable more renewable energy and ultimately reduce carbon emissions. However, battery production is not without environmental impacts. In fact, increased manufacturing of the incumbent battery technology, lithium-ion, presents a new set of challenges: tenuous supply chains, safety, and environmental impacts are all of concern.

The environmental challenges of lithium-ion

Today, lithium-ion batteries provide cheap, but somewhat limited, energy storage, making it a technology of choice for many developers and utilities. However, the low price tag belies significant environmental and social costs. Lithium-ion technology requires scarce minerals, such as cobalt and nickel, which are frequently sourced from geopolitically challenging regions lacking environmental and human rights protections. In addition, lithium mining requires ~500,000 gallons of water per ton of material, which is especially concerning given that over half of the world’s lithium resources are located in arid regions, such as the desert salt flats of Bolivia, Chile and Argentina. In these areas, water must be transported to mine sites, further increasing the impact of mining operations. Lithium mining is also highly carbon intensive, with approximately 15 tons of CO2 emitted per ton of lithium mined.

Iron flow batteries demonstrate the lowest climate and environmental footprint

This is why we’re especially proud of the work we do at ESS to deploy iron flow battery technology which not only enables decarbonization of the grid, but which does so by leveraging a responsible supply chain with a low carbon footprint.

ESS’ long-duration energy storage systems are powered by earth abundant, non-toxic ingredients – iron, salt and water – and ideally complement renewable generation by providing up to 12 hours of storage. Containing one-third the embodied carbon emissions of lithium-ion batteries, ESS’ systems leverage a predominantly domestic supply chain and use widely available materials, increasing flexibility and reducing impacts.

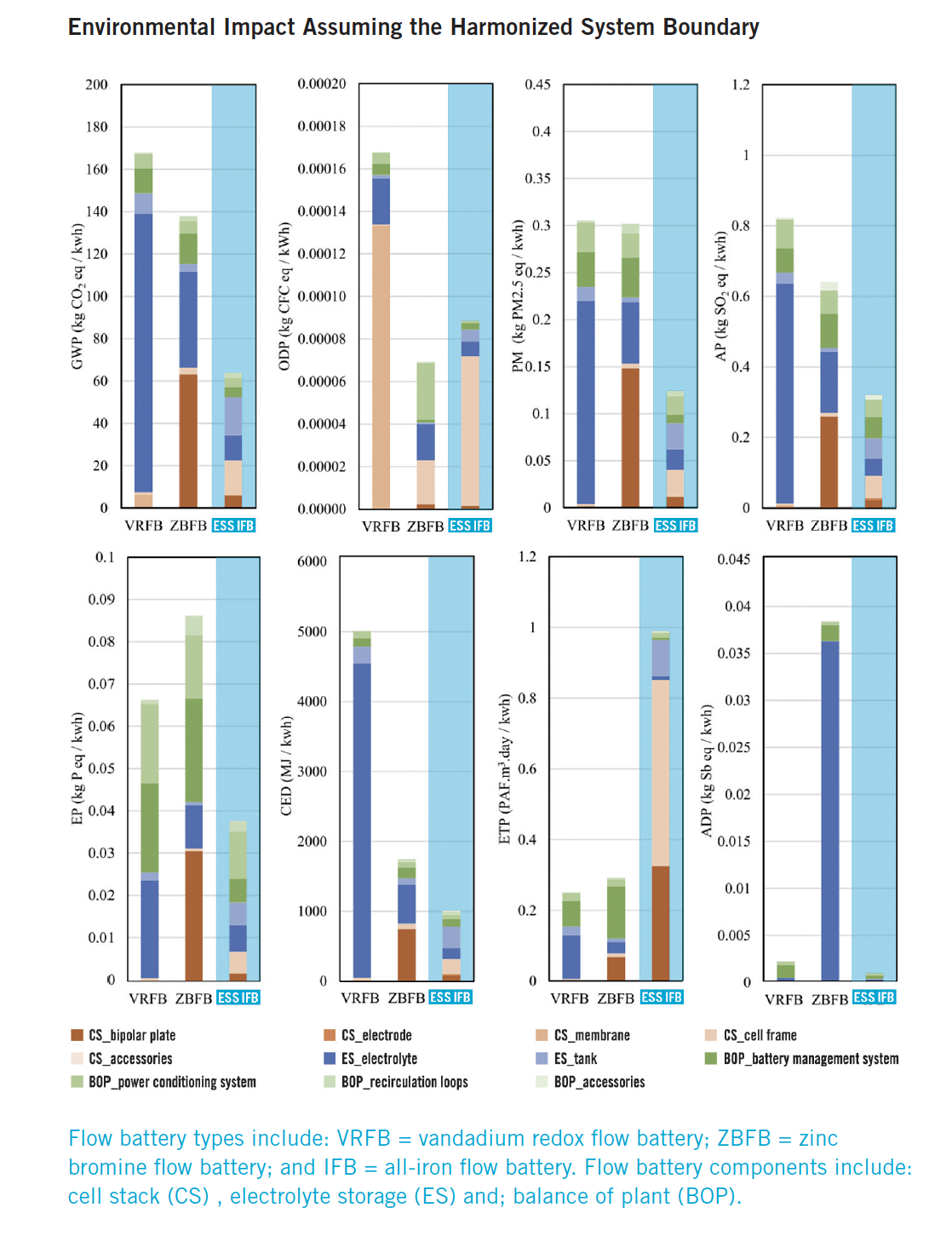

A study by researchers at University of California, Irvine found that iron flow technology has the lowest lifecycle carbon footprint of any competing energy storage technology. Researchers put iron flow batteries head-to-head with vanadium- and zinc-based flow batteries, finding that iron flow to be the cleanest in six out of the eight environmental impact factors measured. Those factors included global warming potential, particulate matter pollution, freshwater pollution and more.

Today’s actions will define tomorrow’s impact

As energy storage deployments accelerate, decisions made today will have carbon implications for decades. Lithium-ion batteries typically require “augmentation,” or, the replacement and/or addition of new cells partway through a project’s operating life, to maintain full capacity. This means that not only is a lithium-ion system more carbon intensive today, it will require the addition of more carbon-intensive materials throughout its operational life. As utilities, project developers and other large energy users scale their energy storage infrastructure, they must consider the full environmental implications of those investments to minimize current and future impacts.

This Earth Day, we find ourselves at an important moment in the clean energy transition. As new clean energy technologies, including long-duration energy storage, come of age and grow from megawatt-hour to gigawatt-hour scale, we’re building a system that can better use current renewable generation while laying the groundwork for the continued shift to wind and solar. It is an incredibly exciting time to be in the business of building the clean energy future and I am optimistic that we will meet the challenges ahead if we lay a sustainable foundation.