Iron Flow Chemistry

The foundation for a secure, reliable grid

Unlimited

cycle life

8-22 hours

of energy storage

Safe and Sustainable

25-year

design life

ESS Tech, Inc. (ESS) has developed, tested, validated, and commercialized iron flow technology since 2011.

ESS’ iron flow chemistry delivers 25+ years and unlimited cycling with no capacity fade or degradation.

Safe and sustainable to source, build, and operate

ESS technology is easy to site and safe to operate. Iron flow chemistry relies upon broadly available materials without critical minerals such as vanadium, lithium or cobalt, and is built leveraging a predominantly American supply chain, supporting energy security and ensuring reliable availability. Our technology is engineered for flexibility and scale to deliver gigawatt-hour storage and meet the demands of an evolving grid with no degradation or capacity fade. It is purpose-built to solve long-duration energy storage.

Can be deployed anywhere from densely populated neighborhoods to regions prone to wildfires.

Secure, domestic supply chain minimizes risk and climate impact.

Clean technology through full life cycle

ESS iron flow batteries can reduce the need for fire suppression equipment, secondary containment, or hazmat precautions. ESS systems are substantially recyclable or reusable at end-of-life.

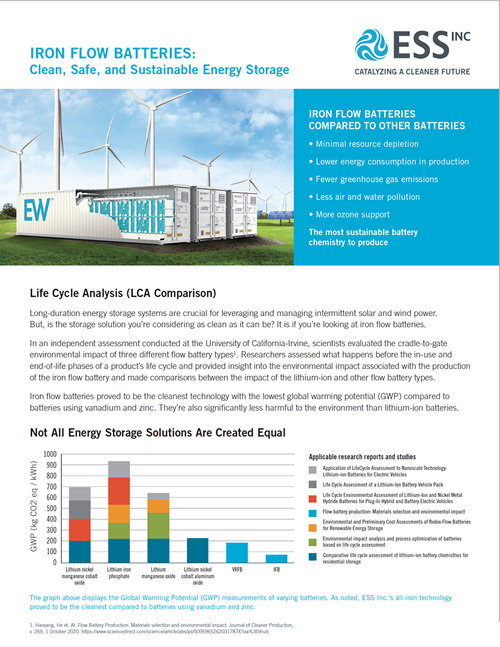

In collaboration with UC Irvine, a Lifecycle Analysis (LCA) was performed on the ESS Energy Warehouse™ iron flow battery system and compared to vanadium redox flow batteries (VRFB), zinc bromine flow batteries (ZBFB) and lithium-ion technologies. Researchers assessed the manufacturing, use, and end-of-life phases of the battery lifecycle. Their findings were clear:

Iron flow batteries proved to be the cleanest technology with the lowest global warming potential (GWP).

For detailed information, download our LCA comparison of iron-flow batteries to lithium-ion and other types of flow batteries.

Storage flexibility that maximizes value

A competitive total cost of ownership over a 25-year design life ensures that our customers will reap the benefits of our long-lasting and reliable energy storage solutions. By strategically driving down costs with our innovative technology, we are on track to meet the DOE’s ambitious LDES cost target of $0.05/kWh by 2030. Implementing fully automated production enhances manufacturing efficiency and consistency and propels ESS towards achieving economies of scale in production. Furthermore, our utilization of standard, widely available components not only streamlines production processes but also significantly reduces costs.

Flexible and cost-effective

Unlimited cycling without degradation or capacity fade

Allows for maximized value with revenue stacking

Operates at wide range of temperatures

Scalable for a wide range of energy needs

Competitive total cost of ownership over 25-year design life

Designed to meet customer needs

Enhanced electrolyte health management

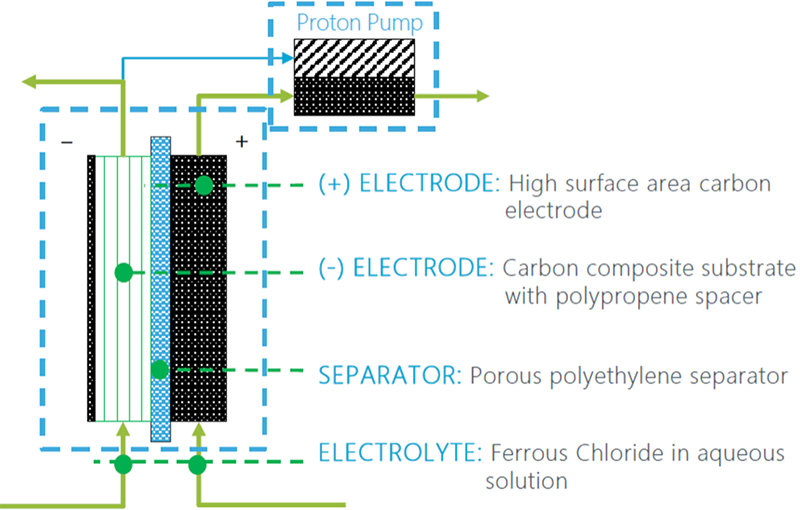

The ESS electrolyte health management system eliminates the need for frequent downtime for recovery or rebalancing required with other flow battery systems.

The ESS iron flow battery uses the same electrolyte on both positive and negative sides. And the proton pump maintains the state of charge and battery health.

Meeting the energy needs of today and tomorrow

While competing non-lithium technologies are still in the lab, our advanced LDES technology is field-proven and already deployed worldwide. Iron flow technology is engineered for flexibility and scale to meet future energy storage demand.